Laser Marking Systems for Every Requirement

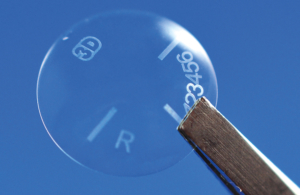

3D-Micromac‘s customers can choose between premium-quality excimer laser systems and high-quality maintenance-free DPSS laser systems. Both are suitable for the production of technical engravings and visible brandings on blocked and unblocked lenses as well as contact lenses.

The microMARK™ MCF excimer laser system generates the engravings by cold laser ablation of 193 nm UV radiation. This results in a superior engraving quality considering all cosmetic aspects – without any heat affection and micro cracks. The industry-approved microMARK™ MCF system guarantees maximum throughput and availability.

With the laser system microMARK™ RXe 200, 3D-Micromac has revolutionized the efficiency of blocked lens engraving by using excimer lasers. Focus is put on an unique optical set-up and engraving quality. Customers benefit from low investment and small operating costs.

In addition to the already proven excimer technology, 3D-Micromac offers the compact and maintenance-free DPSS laser system microMARK™ MCL to meet customer’s demand for high-quality marking with significantly decreased cost of ownership. The system is utilized for visible, invisible as well as for technical engravings of all kinds of spectacle lenses, including CR39, polycarbonate, high-index materials and even mineral glass. Furthermore, it is possible to mark hard and soft contact lenses. The use of a UV DPSS laser source achieves a high-quality marking result comparable to excimer laser engravings.

Industry-approved since 2004

3D-Micromac started the development of excimer laser engraving systems in 2004. With over 200 systems installed worldwide and about 80 percent global market share of all premium labeling systems for ophthalmic and contact lenses, 3D-Micromac now is the market leader in the field of ophthalmic marking systems.

The worldwide available service team of 3D-Micromac supports customers through-out the whole life cycle of their engraving systems. In addition, 3D-Micromac has a fully equipped application laboratory with experienced process engineers that support customers in feasibility tests, process development, and realization of customized solutions.